Technical Committee 303-PFC

General Information

Deputy Chair: Dr Dirk LOWKE

Cluster A

Subject matter

3DCP is an Additive Manufacturing process. It uses digital models of the desired geometries to drive the manufacturing process by digitally slicing the 3D object into a number of layers, spaced at an equivalent distance to the deposition layer thickness the machine uses. The cement mortar is initially a dry blended powder mix with a number of constituent ingredients which typically might be aggregates (sand), cement (a fine powder), fillers, often industrial wastes such as silica fume and water.

The materials vary in characteristics because they are natural products or by-products of other industrial processes. Even the manufacture of cement produces significant variations in the reactive compounds from batch to batch. The shape, size and grading of these constituents along with environmental conditions all affect how the fresh material behaves when pumped and deposited and how the material hardens. This process is strongly time-dependent and the specific conditions, under which a layer of fresh material is placed on an older one, have consequences for the strength of the joint formed.

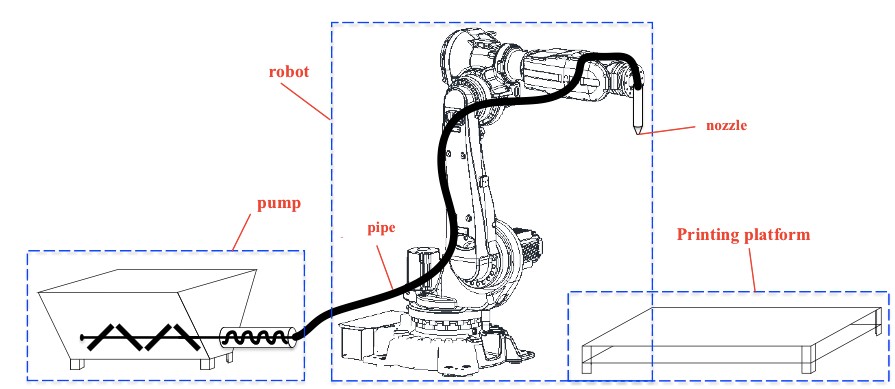

Figure 1 depicts a typical configuration of a 3DCP printing system. Here, the dry material is mixed elsewhere in a batch, where admixtures might be added to fine-tune fresh properties. This mixing might also be carried out continuously. The material is placed in the hopper of the pump and conveyed, often by a positive displacement pump, down a supply line to a nozzle where it is extruded and deposited. The deposition rate and nozzle diameter might be varied, and the robotic arm provides a means of positioning the deposited filament. A mixing chamber might also be placed in the nozzle so that other admixtures might be added that can help to tune the stiffening of the material.

The geometric quality of manufactured parts is not only affected by the precision of the printing but also by the deformation under self-weight during manufacture. The time dependent characteristics of cement hydration and hardening plays a significant role in the performance of the resultant material and printed element. Fresh material must initially remain fluid enough to facilitate deposition and inter-layer bonding during manufacture, but materials that are too fluid can lead to buckling and collapse of structures under the increasing weight of the successive layers. The importance of these mechanisms has driven significant efforts in recent works: determining the rheological requirements of the fresh material; quantifying buildability; and predicting structural failure for controlling deformation behaviours. Undesirable effects can be exacerbated by poor control of material delivery, filament placement and toolpath planning. Being able to measure, assess and benchmark process and material performance using standardised and internationally accepted approaches is therefore essential for the industrial future of the technology.

Figure 1: Layout of a 3DCP system.

Terms of reference

This TC will deal with the performance of the printable material in its fresh state and the performance of the delivery system.

Constituent-based specification of materials (such as the European standard EN206) is unhelpful with 3DCP materials because of the complicated trade-offs required to satisfy the multiple criteria that allow these materials to be pumped, to remain stiff and correctly located in the printed component and to resist buckling while maintaining good interlayer bonding, all of which are influenced by the design geometry and the toolpath. The work here will underpin the development of performance specification of printable materials.

The active control of the material in terms of hydration and workability is a requirement to treat the variable nature of cement and the constituent components of the mix. These are natural-sourced materials, and variability of properties can be controlled through careful mix preparation, but cannot be eliminated to the extent that yields reliable printing without active control. Hence, the material delivery system includes pumping and admixture dosing operations, which also must be evaluated to ensure a specified performance given a particular material mix.

This TC will tackle three main topics:

- Performance specification of the fresh properties of printable materials.

- Measurement of the fresh properties of printable materials.

- Evaluation of delivery system performance.

The outcomes will be methods of performance assessment, measurement and specification that can be used to establish quality control for printing systems and materials for industrial application.

Detailed working programme

The program is the following one:

1. Performance specifications of the fresh properties of printable materials

Objectives: To define fresh properties requirements for printable materials as a function of printer and printed object.

Expected Results:

- Definition of boundary values and tolerances for fresh properties requirements (deliverable)

- Definition of categories and classification for potential printable materials (deliverable)

2. Measurement of the fresh properties of printable materials

Objectives: To develop measurement protocols for industrial quality control of printable materials fresh properties.

Expected Results:

- Measurement protocols and recommendations for industrial quality control of fresh properties requirements (deliverable), both targeting average value and variability.

- Assessment of repeatability and reproducibility of the measurement protocols at the level of the TC network and of all partners.

3. Evaluation of delivery system performance

Objectives: To develop evaluation protocols and recommendations for the qualification and certification of printing heads and material supply system in terms of material homogeneity and printing robustness.

Expected Results:

- Evaluation protocols for the efficiency of the mixing, feeding and dispersing systems in a printing head at a generic level (deliverable)

- Requirements in terms of residence time and material homogeneity for a printing head as a function of material and process parameters (deliverable)

The working program will include literature reviews, round-robin tests and other activities related to preparation of the above listed deliverables. Furthermore, activities of the committee will include (co-)organizing international RILEM conferences on digital concrete construction.

In a first step, existing potential tests for fresh printable materials will be listed along with their pros and cons. The ability of these tests to assess printable materials will then be tested by all members on their specific printing facilities in a inter-laboratory test that is still to be defined.

Technical environment

The proposed TC is a follow-up of TC 276-DFC “Digital fabrication with cement-based materials” lead by Prof. N. Roussel. The state-of-the-art report of the RILEM TC 276-DFC and other publications resulting from its work gave an account of the opportunities and challenges related to the use of new technology. On the TC meeting in January 2020 it was decided to initiate two follow-up RILEM technical committees: one focusing of processing chain and characterization of fresh concrete in the context of digital fabrication and another one dealing with properties of hardening and hardened print concrete and structural elements.

The work of the committee is related to a number of other technical committees of RILEM dealing with rheology and rheology measurements. The work on recommendations will provide input to relevant standardization and pre-standardization work within ACI, ISO, fib, ASTM, NIST etc.

The work will be carried out in connection with national or multi-national local groups involving practitioners as mentioned in the proposed terms of reference.

Expected achievements

Expected achievement

- Recommendations for the practitioner

- Reports on results of round-robin tests

- International RILEM conferences incl. proceedings

- RILEM PhD courses

- Joint publications by TC members

Results diffusion

- During the tenure of the TC: publication and presentations of the ongoing results by their respective authors (in scientific journals and conferences)

- Reports in “Materials and Structures”

- Proceedings of the RILEM Conference

- At the end of the TC tenure: Publication of Recommendations.

Group of users

The targeted users are researchers, practitioners and standardization bodies in the field of concrete technology.

Specific use of the results

The recommendations to be developed by TC should facilitate the introduction of this new technology into the practice of construction. The digital concrete fabrication offers new possibilities with regard to increasing productivity for concrete construction and enhancing its flexibility and sustainability. A considerable economic impact can be expected due to the benefits connected with its industrial utilization.

Through the local national or multi-national groups specified in the proposed terms of reference, the practitioners are envisaged to implement the TC’s recommendations in their respective countries until the adoption of national or international standards.