Technical Committee MCA

General Information

Deputy Chair: Prof. Arezou AHMADI

Cluster A

Subject matter

This TC seeks to improve our understanding of how mechano-chemical processing routes can be used to increase the chemical reactivity of a range of mineral-based materials, for use in cementitious materials. Mechano-chemical activation refers to the use of intensive grinding that increases the extent of structural disorder in a mineral’s crystal structure (i.e. amorphization) and can also induce certain chemical reactions (e.g. dehydroxylation of clay minerals).

This TC would primarily carry out inter-laboratory testing, supplemented by some literature review and modelling work. The key attributes of mechano-chemically activated materials investigated will be: extent of amorphization; phase composition and transformations; chemical reactivity; particle size distribution, specific surface area and colour. The TC will primarily focus on the mechano-chemically activated materials themselves. Investigation into properties of cementitious pastes and mortars incorporating mechano-chemically activated materials (e.g. reaction kinetics, fresh state properties, strength) will be defined within the relevant working groups (WGs), allowing for the exploration of either blended cement systems or/and alkali-activated systems, depending on the focus and objectives of each WG.

The basic chemical principles of mechano-chemical activation have been known for >50 years. But recently, there has been a dramatic increase in academic and industrial interest in this approach, in order to increase the reactivity of some cementitious constituents and valorise waste streams. Whilst the premise of mechano-chemically activated constituents has been demonstrated at the laboratory scale in several studies, there are still numerous fundamental and practical knowledge gaps which are a barrier to wider industrial adoption. We believe that several of these knowledge gaps are best addressed using a community-based approach, in particular inter-laboratory experimental tests (see Section 4 for details). This topic has not been addressed experimentally by any previous RILEM TCs.

The limits of scope in terms of materials considered would be mineral-based material streams which are widely available and not currently activated by other means. This includes both natural resources (inc. common clays, natural pozzolans) and industrial by-products and wastes (inc. mine tailings, slags, construction and demolition waste). The limits of scope in terms of the value chain would be: mechano-chemically activated materials, cement pastes and mortars. Concrete would be excluded, as at this point in time, not enough members would have the necessary equipment to mechano-chemically activate sufficient material for concrete production. Other activation routes, such as thermal activation and acid activation, would be excluded. Combined thermal and mechano-chemical activation is potentially within scope, and would be discussed within the working groups.

Mechano-chemical activation has so far shown particular promise for mineral resources which are not effectively activated via thermal activation (i.e. calcination). These are often present in industrial by-products (e.g. excavation waste, mine tailings). Therefore, enhancing capabilities in mechano-chemical activation has the potential to valorise waste streams and waste stockpiles, whilst also helping to meet the growing global demand for SCMs.

Terms of reference

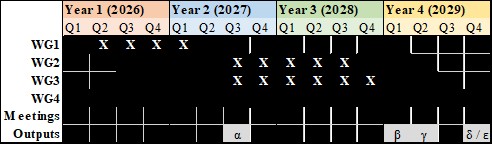

The TC is proposed to run over a period of 4 years – the main experimental activities are anticipated to be completed within the first 3 years, with the 4th year principally dedicated to discussion of results, writing and dissemination activities (see Gantt chart overview below).

Meetings will be held every three months, and will alternate between in-person meetings at major conferences (Q1 and Q3), and online meetings (Q2 and Q4).

Key for Gantt chart:

X = indicates when inter-laboratory testing campaigns are likely to be carried out

A = RILEM Spring Convention 2026 (Ghent, Belgium)

B = RILEM Week 2026 (Nairobi, Kenya)

C = RILEM Spring Convention 2027 (Thessaloniki, Greece)

D = 17th International Congress on the Chemistry of Cement (New Delhi, India)

E / G / H = In person meetings, to be planned

F = 19th AIPEA International Clay Conference (Location TBC)

O = online meetings

Outputs key for Gantt chart:

α = Experimental research article – ILT from WG1

β = Experimental research article – ILT from WG2

γ = Experimental research article – ILT from WG3

δ = Modelling and embodied energy research article – WG4

ε = Summary of recommendations

There is already growing industrial interest in mechano-chemical activation, with Schwenk Cement and Polysius announcing their commercial Meca-clay product. Other companies are also known to be working on mechano-chemical activation. This TC will have direct relevance by developing increased knowledge and guidelines for materials selection, processing conditions, and standardized testing methods.

Much of the research into mechano-chemical activation of SCMs has so far taken place in Europe, with clusters of research also taking place in China, India, North America and Australia. Given the growing interest in this topic, and the scope of a range of mineral resources which are found worldwide, it is anticipated that this TC will attract a diverse geographic membership. We anticipate a range of 20-30 active participants, and 30-50 observers. Since the topic is relatively new, there are opportunities for new RILEM members to get involved from both academia and industry.

Detailed working programme

The main activities proposed for the TC are divided into four working groups (WGs):

- WG1: Repeatability of MCA and characterisation. The aim of WG1 is to establish the repeatability of the MCA process and key characterisation techniques between the participating labs. This will serve as a foundation for the other WGs’ activities. For the WG1 ILT, a selection of materials will be distributed to participating labs, and MCA carried out in a planetary ball mill apparatus using an agreed protocol that describes a common set of milling conditions. Key parameters will then be measured, e.g. particle size distribution via laser diffraction, extent of amorphization via XRD. Reactivity tests will be discussed and selected to assess reactivity, as relevant to different cementitious systems (e.g. R3 test for blended cements, dissolution in NaOH for alkali-activated cements).

- WG2: Universality of MCA processes. The aim of WG2 is to investigate the extent to which the MCA phenomena are universal over different milling apparatus, and to what extent they are distinct. For the WG2 ILT, a selection of materials will be distributed to participating labs, and MCA carried out using different milling apparatus available to WG2 participants (e.g. planetary ball mill, disc mill, tumbling ball mill, attritor mill, SPEX mill). Key parameters will be measured (e.g. particle size distribution, extent of amorphization and reactivity), to evaluate the similarities and differences between different milling apparatus.

- WG3: Effect of milling environment on MCA processes. The aim of WG3 is to identify which grinding environments can make MCA more efficient for different types of materials. For the WG3 ILT, a selection of materials will be distributed to participating labs, along with protocols for MCA in a planetary ball mill (based on those tested in WG1). Different milling environments will be tested, depending on capabilities of milling apparatus available to participants e.g. use of water or isopropanol; N2 or CO2 gas, grinding aids. Key parameters will then be measured (e.g. particle size distribution, extent of amorphization and chemical reactivity), to evaluate whether certain environments can make MCA more efficient or effective for certain constituents.

- WG4: Modelled and measured energy inputs. The aim of WG4 is to evaluate the effectiveness of predictive models for energy consumption, and improve our understanding of how grinding parameters affect reactivity. This can include reviewing literature models to estimate the energy inputs in different milling apparatus; and using these to model energy input for the ILT experiments carried out in WG1 and WG2. In parallel, the measured energy consumption from the experiments in WG1 and WG2 can be used to analyse ‘activation efficiency’ with regard to the energy consumed in comparison to the chemical reactivity achieved.

Technical environment

This TC is anticipated to build on the work of previous TC: applying the R3 test developed in TC 267-TRM (Tests for reactivity of supplementary cementitious materials), and the understanding of calcined clays as SCMs developed through TC 282-CCL (Calcined Clays as Supplementary Cementitious Materials). The choice of reactivity tests will be selected through WG1’s activities, and may include some of the emerging tests developed by TC 298-EBD (Test methods to evaluate durability of blended cement pastes against deleterious ions), e.g. paste conductivity measurements.

We have discussed this TC proposal with key members of current TC 321-UMW (Upcycling Powder Mineral “Wastes” into Cement Matrices, 2022-2027). A desk review of mechano-chemical activation of mineral wastes is included within the activities of their WG2 “Utilisation of mineral wastes in clinker-derived cementitious matrices”; however, no experimental work is planned. We plan close cooperation between this proposed TC and TC 321-UMW, and anticipate that the desk-based outcomes from WG2 of TC 321-UMW can help inform the experimental plans for inter-laboratory testing in this proposed TC. There is also potential for links with current TC 309-MCP (Accelerated Mineral Carbonation for the production of construction materials) for MCA in a CO2 atmosphere as part of ILT3.

Expected achievements

The anticipated deliverables from this TC are:

- Research articles: these will correspond to the outcomes of the three proposed inter-laboratory tests (to be published in Materials and Structures), and an article around modelling and measurement of embodied energy in mechano-chemical activation. For anticipated timings, see Gantt chart in Section 3.

- Recommendations: in the final year, it is planned to publish a set of recommendations (in Materials & Structures) around MCA, based on the key learning points from the TC’s activities. This is anticipated to include (but not be limited to: nomenclature around mechanical and mechano-chemical activation, and methodological reporting conventions for mechano-chemical activation so it is repeatable.

- Workshops on MCA: To be arranged in Years 4, as part of other major conferences or events.

- Explanatory videos: To be produced in Years 4, as YouTube videos which give introductions to the key phenomena and process aspects of MCA, that are accessible to a general audience.

Group of users

Academics and industrialist working in the cementitious materials supply chain, and also in sectors with waste materials relevant to valorisation (e.g. mining and quarrying companies).

Specific use of the results

Our expectation is that the work of this TC will improve our fundamental understanding of the structure-processing-property-performance relationships in the use of mechano-chemically activated clays as SCMs. We anticipate that this will stimulate the wider development of mechano-chemical activation approaches in academia and industry, particularly outside of Europe and for a wider range of materials than those typically studied so far.